In the heart of North Texas, Alston Construction transformed a portion of an existing facility into Hungryroot’s largest distribution center—a cutting-edge hub designed to streamline operations across the West, South, and Midwest regions. This project was more than a standard improvement; it was a fast-paced, high-stakes collaboration that combined precision construction with advanced logistics and automation.

Hungryroot Tenant Improvement | Denton, TX

From Vision to Reality

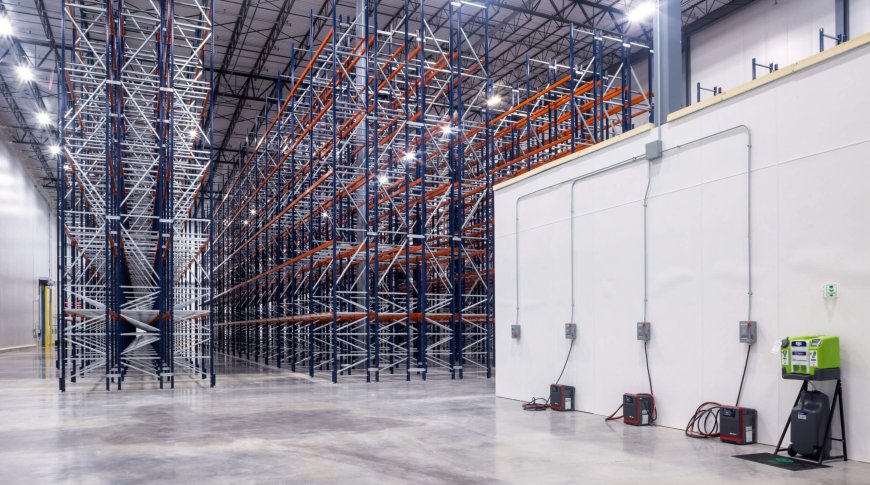

The project scope encompassed roughly one-third of the building, delivering a full-service package distribution center for Hungryroot. The space included demising IMP walls separating freezer and cooler areas equipped with robotic racking systems, an ambient storage area with partial office spaces, a custom bubble wrap packaging station, and a cold dock area complete with conveyors. Every detail was tailored to support Hungryroot’s mission: efficient, high-volume packaging and distribution of fresh ingredients directly to consumers.

From removing ingredients from the freezer, through robotic handling and packing, to conveyors transporting orders to shipping personnel, every step of the operation was engineered for seamless workflow. This facility not only became the company’s largest distribution hub, but a critical node in their nationwide network—relieving pressure on other regional centers and enabling future growth.

Overcoming Challenges

The project carried an aggressive eight-week schedule and required swift response to evolving operational needs. As Hungryroot refined workflows during construction, the scope expanded significantly—ultimately increasing by nearly $2.2 million to support added systems and functionality.

Teams worked within tight site constraints, at times coordinating 104 workers simultaneously and up to 32 individuals within office construction areas alone. Despite the intensity of the build, Alston maintained strict safety practices through daily communication, toolbox talks, and active site supervision—ensuring crews could execute efficiently and safely.

Collaboration and Coordination

Success hinged on collaboration. Alston worked closely with Hungryroot, the architect, the building owner, and key subcontractors to adapt to design and operational updates in real-time. Precise coordination was essential for electrical drops, conveyor routing, and robotic layouts, which often required rapid modifications to CAD plans.

Trade partners such as Intex Electrical were instrumental in executing the power distribution and automation requirements. A strong working relationship between the field team, project management, and subcontractors fostered a problem-solving environment where decisions were made quickly to maintain momentum.

Delivering Ahead of Schedule

Through strategic planning, proactive material procurement, early identification of long-lead items, and fast-paced field coordination, Alston Construction delivered the project nearly a month ahead of the contractual date. Even with extensive scope additions and operational adjustments during construction, the team achieved a fully operational facility that exceeded expectations.

Lessons Learned and Best Practices

The Hungryroot project highlighted the value of:

• Skilled trades experienced in interior renovations and cold environments

• Adaptability and quick decision-making in accelerated construction settings

• Open, real-time communication among all stakeholders

• Advanced planning for procurement, logistics, and technology integration

By merging automation, logistics, and specialty construction in a compressed schedule, Alston delivered a distribution center prepared to support high-volume fulfillment today and scalable growth tomorrow.

Setting a Benchmark

The Hungryroot distribution center stands as an example of what can be achieved when expertise, innovation, and alignment come together. It reinforces Alston Construction’s ability to execute complex tenant improvements with speed and quality—setting the standard for future-ready food distribution hubs nationwide.